The Thunderbike Named the 2012 AMD World Championship Of Custom Bike Building

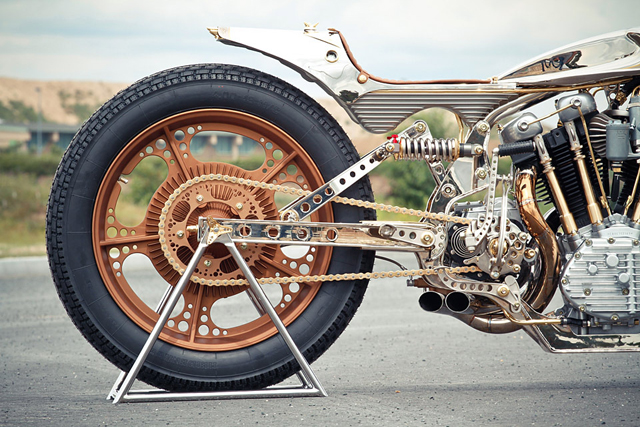

/The detailing on the Thunderbike "PainTTless" is impeccable! Each component was developed from scratch during the 8 month construction period by the motorcycle heavy weights at Harley Davidson. The custom bike has just been named the AMD World Championship Of Custom Bike Building in Sturgis 2012. "We gave everything and were rewarded with the coveted world title in the Freestyle class. With one of our most unique custom bike," the moto-makers explained. Deep thought, planning, and preparation was put into creating the "PainTTless," which is driven by a very expensive rebuilt 1000 cc Harley-Davidson Ironhead engine installed in early Sportster models. The builders "were inspired by the racers of the 1930s, which often came on dry salt lakes in the U.S. are used."

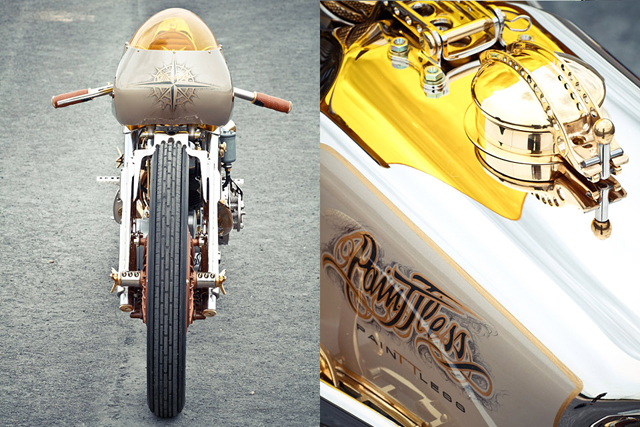

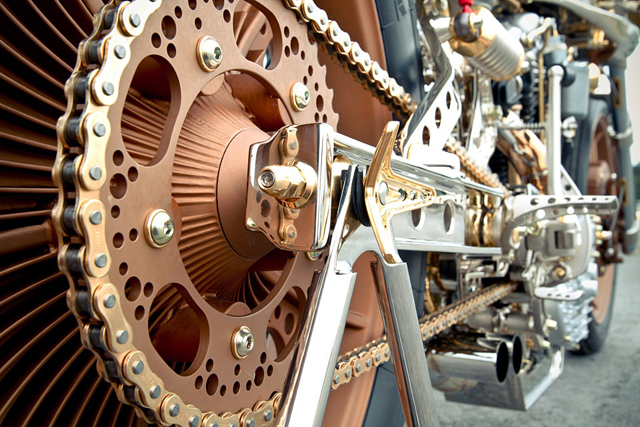

Andreas Berger Forth of Harley Davidson says "we decided to build a bike for the AMD World Championship Of Custom Bike Building in Sturgis." The bike is made with "no paint, no varnish, no powder, no filler, no tin! Only those who have ever heard made to chrome knows what this means. The preliminary work has to be absolutely perfect!"

The motorcycle is anything but ordinary. Thousands of unique parts were designed for the making, no part came from the shelf or the catalog. So many new parts were birthed from this project that an entire website page was created to explain and sell the parts. The process was so intricate, we decided to let Fourth explain in his own words.

"Next we have derived from the first sketches a sheet metal silhouette, to put some wheels and set so the rough proportions of the future racers."

"Then we went to the frame, the shoe plate for the engine and transmission. Combined with the pipe coating, he brings the necessary character in the racing bike. After we started so it can be useful to swing to a combination of flat steel and pipe. The first holes to be drilled!"

"Since we wanted a free standing hump we had to find a different kind of swing deflection, laterally arranged under the bump shocks fit perfectly there. Humps and tank were first contacted with plywood and cardboard in the form. For this, the metal silhouette and the first sketches were used as a guide."

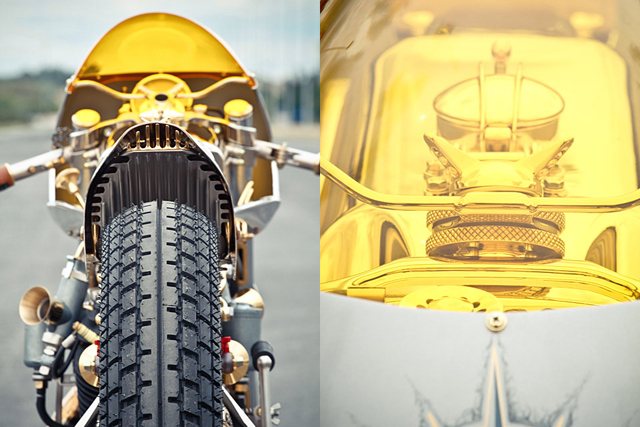

"The fork of a different kind, a combination of jumpers and fork with two dampers is a real gem and works very well. Shortened springs Streetbob a fork combined with two bike dampers. Unusual? Yes! Clean response? Yes! Fittingly Negativweg? Yes! Direct hit!"

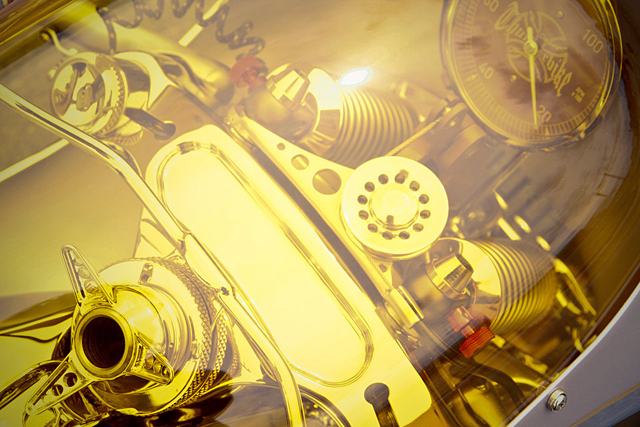

"Now that the chassis and engine are grossly's off to the functions: braking, clutching, shifting, choke, advance mechanism, gas, pegs, levers, deflections, poles, trains, and much more - just all the controls."

"Speaking of ignition: The way there was very rocky. The Lima away the detonator out. Sounds easy? Yes, but - the translation does not fit naturally. The ignition must 1:1 rotate the crankshaft, which means - matching pinion must be made and the bearing seats are rearranged. On that occasion it has to take a mill a new cam cover for the old man no longer fits well. Oh, one turning mounted securing the magneto still needs so that you can also adjust it afterwards. Child's play?"

"The hump gets his bodywork. Next, it's going to tank. A component of the difficult way - mainly because after all supposed to be "paintless". To achieve this, the surface must be perfectly clean, without the smallest dent. This block is used as a form of 3D-machined plastic tank. Cautious hours hammering and welding pass. The result is really impressive!"

"The hardest part of this project, however, is the cover. The same game with the tank only viiieeeel consuming. Mill until a plastic model, then artfully formerly the plano piece of sheet metal, wrinkle free knocking around. With an air hammer, the sheet is stretched to the extreme curves and brought so millimeters in shape. To reach the complex form, it must be cut in the sheet metal, welded back clean and so on. Finally, set a carbon fiber hood to the precise cutout for the fork."

"If even a Bosch magneto, then Amal carburettor namely TWO - this must be possible? Possible yes, but not easy. Take a second rear cylinder head rotates it 180 degrees and installed it again. It sounds simple. But the side effects are not without. New oil wells must be placed into the cylinder, slide guides milling new, reworked rocker. On that occasion, can also equal the lower fins and turned the rocker boxes are shared - brings true Old School look. For the primary side there is then a new cover, with an adjustable chain tensioner, a new gear for the crankshaft with Sporty shank and WLA duplex chain pitch. Oh, fancy new pushrod tubes and outer brass pipes for Kipphebelschmierung and ribbed intake is of course available too."

Photography Credit: Dirk Behlau